Products

Our products

Precision and quality - Made in Germany

Retractor

Our retractors stand for absolute precision and the highest quality workmanship, which are essential in the sensitive field of surgery. Manufactured from first-class materials, they guarantee durability, reliability and maximum safety in the operating theater. Each instrument is created by precise laser cutting, exact laser welding and high-quality surface finishing.

As a German manufacturer, we attach great importance to craftsmanship, state-of-the-art production technologies, strict quality controls and short delivery times – directly on site. Place your trust in retractors “Made in Germany” – for surgeons who do not compromise. We also implement individual requirements reliably and precisely according to your specifications.

Mouth guard

Our oral irrigators combine maximum precision and uncompromising quality to provide you with an indispensable tool for everyday surgery. Manufactured from high-quality materials, they are characterized by their durability and reliability. A particular highlight of our production is the mass production of the “Molt” retractor models for children and adults.

This efficient production enables us to offer high-quality instruments at an excellent price-performance ratio. Our modern production technologies and strict quality controls guarantee consistently outstanding product quality. Thanks to efficient processes, we guarantee short delivery times and maximum planning reliability. Put your trust in mouthguards “Made in Germany” – for precision and reliability.

Nose specula

Our nasal specula stand for German precision work and the highest quality standards. As one of the last manufacturers to produce nasal specula in Germany, we rely on high-quality materials and state-of-the-art production technologies. Each instrument is manufactured with the utmost care to ensure optimum handling and reliability in use.

Our production combines craftsmanship with innovative technology and guarantees you durable products that meet the requirements of modern surgery. Place your trust in nasal specula “Made in Germany” – for quality that has proven itself worldwide. Of course, we will advise you individually to find the ideal solution for your requirements and also manufacture instruments according to your special wishes.

Special solutions

Our special solutions stand for the highest precision and quality, specially tailored to your individual requirements. We combine the latest manufacturing technologies with craftsmanship to develop customized instruments of the highest perfection. From the initial idea to production – we accompany you through every step and realize your vision in small or large series.

What makes us special? Our flexibility, experience and focus on your needs. With state-of-the-art machines, precise manual work and decades of expertise, we reliably implement even the most complex requirements. We guarantee the highest quality and smooth implementation – from planning to production. Place your trust in special solutions “Made in Germany” – for instruments that leave nothing to be desired.

Additional services

Perfection to the end,

everything from a single source

Precise production does not end with the final cut, only the right finishing makes a product truly perfect. With a wealth of experience and state-of-the-art technology, we ensure that surfaces not only look flawless, but are also functionally impressive. Every detail counts, which is precisely why we rely on careful finishing steps that guarantee quality, durability and the highest standards of purity.

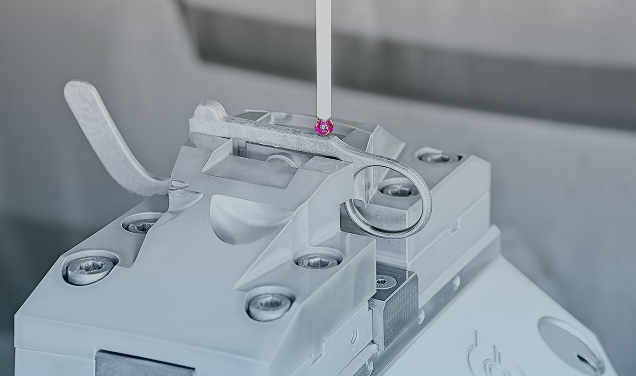

Laser marking

Clear and durable markings are essential in medical technology – whether for traceability, serial numbers or individual markings. With our in-house laser marking, we guarantee precise and abrasion-resistant engravings that withstand even intensive use and sterilization processes. Thanks to the latest laser technology, we can produce the finest details in razor-sharp detail without impairing the material properties.

- Durable, abrasion-resistant marking for traceability

- Precise and rust-free marking thanks to ultra-short pulse laser

- Made in Germany - for maximum quality standards

- Individual labeling for surgical instruments

Sandblasting

You can recognize a high-quality product not only by its function, but also by its surface. With our in-house sandblasting process, we ensure an even, matt surface that is not only visually appealing, but also offers functional benefits. Low-reflection surfaces improve the handling of surgical instruments, while targeted structuring optimizes durability and grip.

- Uniform, low-reflection surfaces for optimum handling

- Improved grip & durability through targeted structuring

- Made in Germany - for maximum quality standards

- Customization and material-friendly processing

Final cleaning

Flawless surfaces and absolute cleanliness are essential in medical technology. Our in-house, validated final cleaning removes even the finest residues from production and ensures that every instrument meets the highest hygiene standards. This is followed by certified passivation, which increases corrosion resistance and ensures documented material purity, and we use precisely coordinated cleaning processes to ensure that your products are ready for immediate medical use – safely, reliably and residue-free.

- Validated cleaning for the highest hygiene standards in medical technology

- Effective removal of the finest residues from production

- In-house final cleaning - Made in Germany

- Certified passivation for optimum corrosion protection

FAQ

Frequently asked questions

Are your surgical instruments ISO-certified?

Yes, our instruments are manufactured in accordance with the strict requirements of ISO 13485 – the international standard for quality management systems in medical technology. Our certified processes guarantee consistently high dimensional accuracy, safety and traceability.

Do you offer customized solutions?

Yes, in addition to our standard range, we manufacture individual custom-made products exactly according to the specific requirements of our customers. Thanks to state-of-the-art production technologies and precise measurement technology, we can implement your designs precisely for a wide range of surgical applications.

What materials do you use for the instruments?

We manufacture exclusively from high-quality, stainless steel that is optimized for medical use. These materials offer excellent corrosion resistance, sterilizability and durability to meet the highest safety and hygiene standards.

How long are the delivery times for your products?

Thanks to our efficient production in Germany, we guarantee short delivery times, depending on the product type and order quantity. Please contact us for an individual delivery time for your order.