Laser Cutting

Your reliable partner for contract manufacturing in laser material processing

Laser cutting

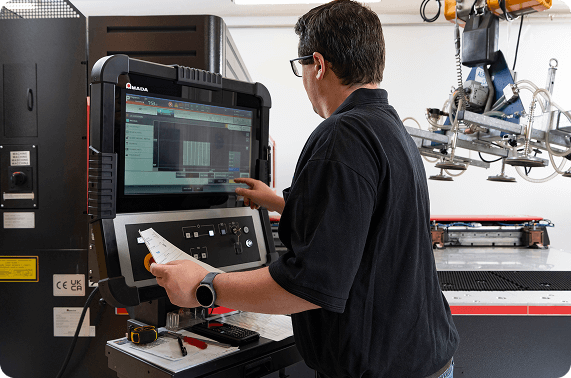

Fast, precise, clean – our laser cutting stands for the highest precision and maximum efficiency. With our two powerful laser cutting machines with 2000 W and 3500 W output, we produce customized metal cuts from stainless steel in thicknesses from 0.5 to 8 mm and sheet formats up to 1250 x 2000 mm. Perfect cut edges without burrs and reworking are our standard – even with intricate geometries and complex contours.

Fast, precise, clean – our laser cutting stands for the highest precision and maximum efficiency. With our two powerful laser cutting machines with 2000 W and 3500 W output, we produce customized metal cuts from stainless steel in thicknesses from 0.5 to 8 mm and sheet formats up to 1250 x 2000 mm. Perfect cut edges without burrs and reworking are our standard – even with intricate geometries and complex contours.

As a German manufacturer, we combine state-of-the-art laser technology with decades of experience to guarantee you the highest quality. Every cut undergoes strict quality controls for maximum dimensional accuracy and surface quality. Thanks to efficient manufacturing processes, we can produce both individual parts and series production in the shortest

time – with fast delivery times, reliable precision and solutions,

that are perfectly tailored to your requirements.

As a German manufacturer, we combine state-of-the-art laser technology with decades of experience to guarantee you the highest quality. Every cut undergoes strict quality controls for maximum dimensional accuracy and surface quality. Thanks to efficient manufacturing processes, we can produce both individual parts and series production in the shortest time – with fast delivery times, reliable precision and solutions,

that are perfectly tailored to your requirements.

Material selection

Stainless steel

Choosing the right material is crucial for the quality and functionality of your components. At Betzler, we have deliberately specialized in stainless steel, as its high corrosion and temperature resistance and mechanical strength make it ideal for demanding applications.

In our material list, you will find a detailed overview of various stainless steel qualities, their properties and available thicknesses. Whether highly polished steels for surgical instruments or spring-hard materials for technical applications – we only supply stainless steel of the highest quality, precisely tailored to your project.

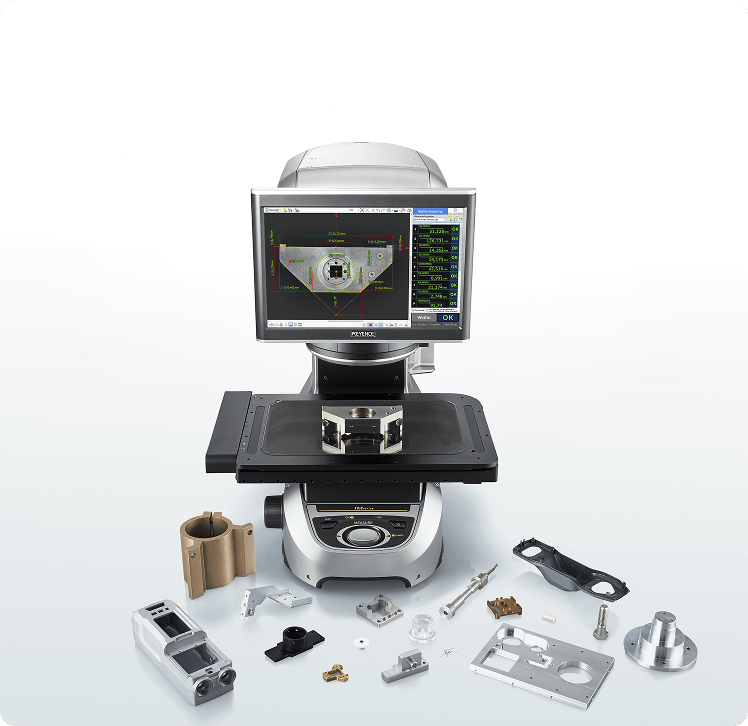

2D coordinate measuring machine

No drawing? Scan, measure, reproduce

Missing technical drawings or damaged tools? With our latest generation digital measuring projector, we can capture components in seconds and transfer their contours precisely into CAD data – without any time-consuming manual measuring work. Thanks to high-resolution image capture and a 360° rotation unit, even complex geometries can be reliably digitized – regardless of whether it’s a single piece or series production.

As a German manufacturer with over 40 years of experience, we offer you maximum measuring accuracy, particularly fast implementation and digital solutions that fit seamlessly into your production processes – efficiently, repeatably and precisely tailored to your requirements.

- Precise digitization of existing components

- Precise CAD data for reworking or customization

- Fast and user-independent measurement processes

Advantages of laser welding

Compared to other cutting processes such as punching, water jet cutting or forging, laser cutting offers decisive advantages in terms of precision, efficiency and flexibility. It enables particularly economical and material-friendly production.

- Even small minimum quantities are cost-efficient.

- High flexibility in shape and material.

- High material utilization / economic efficiency.

- Very fine, often rework-free cutting edges.

- Engraving/marking and cutting possible in parallel.

FAQ

Frequently asked questions

Is one-off production possible or only series production?

We offer both individual items and series production. Thanks to our flexible production processes, we can realize individual solutions – whether prototype, small series or large series.

How fast is the delivery?

Thanks to our efficient processes and production in Germany, we can guarantee short delivery times. The exact processing time depends on the complexity and quantity of your order – please contact us for a binding delivery date.

Which file formats are accepted for production?

We prefer to work with DXF, DWG or STEP files, as these enable precise implementation. If you do not have a suitable file format, we will be happy to help you create one at

.

Who can order from Betzler and where is delivery to?

Our services are aimed at companies in the medical technology, industry, trade and other commercial sectors that require precise metalworking. We supply customers all over the world – regardless of whether it is a one-off production, small series or large-scale production.