Laser Welding

Maximum stability & precision - Your partner for laser welding

Laser welding

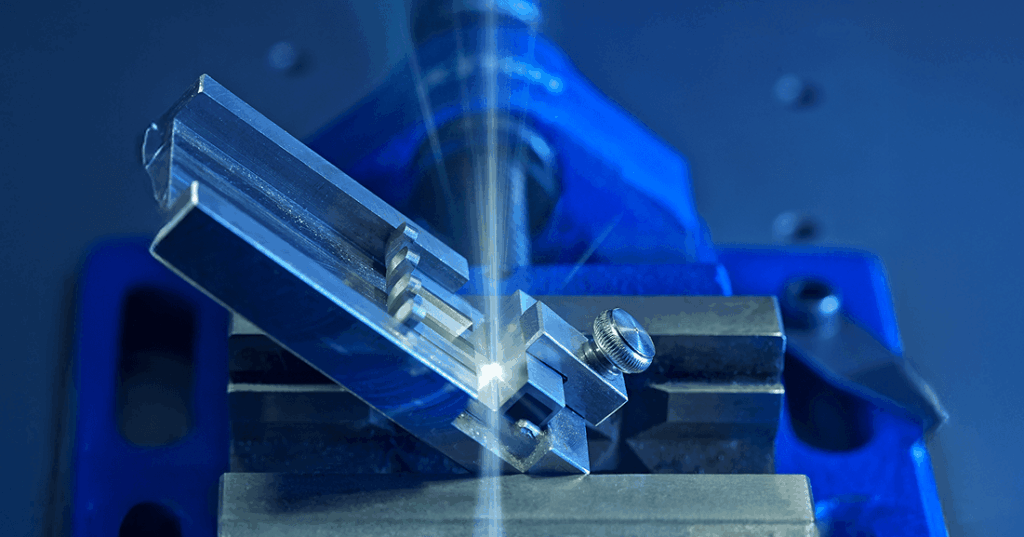

Our laser welding stands for stable connections and flawless precision. Using state-of-the-art laser technology, we produce precise, low-distortion weld seams that can withstand even the highest loads. The minimal heat effects ensure dimensionally accurate results, so that even intricate structures and complex components can be produced with the highest quality.

Our laser welding stands for stable connections and flawless precision. Using state-of-the-art laser technology, we produce precise, low-distortion weld seams that can withstand even the highest loads. The minimal heat effects ensure dimensionally accurate results, so that even intricate structures and complex components can be produced with the highest quality.

As a German manufacturer, we rely on quality-assured processes and state-of-the-art production technologies to guarantee you durable and resilient welded joints. Every component undergoes strict checks to ensure maximum stability and surface quality. Whether it’s a single part or series production – we deliver quickly, reliably and precisely tailored to your requirements.

As a German manufacturer, we rely on quality-assured processes and state-of-the-art production technologies to guarantee you durable and resilient welded joints. Every component undergoes strict checks to ensure maximum stability and surface quality. Whether it’s a single part or series production – we deliver quickly, reliably and precisely tailored to your requirements.

Advantages of laser welding

- Precise, distortion-free welded joints with high dimensional accuracy

- Durable seams without time-consuming reworking

- Targeted heat input for material-friendly processing

- Flexible for complex components & different material thicknesses

- Efficient, fast production for individual & series production

Laser welding

Materials, sizes & precision

Laser welding depends on the right material and the right component sizes. We primarily process high-quality stainless steel alloys, which are characterized by high load-bearing capacity, corrosion resistance and durability. Whether thin-walled precision components or larger workpieces, we weld material thicknesses of up to several millimetres without compromising dimensional

accuracy and quality.

Thanks to the precise control of the laser beam, extremely fine, resilient weld seams are created with minimal heat input – no distortion, no material changes, maximum stability. Even complex contours and filigree structures can be realized with tight tolerances, so that every component is manufactured exactly according to your specifications.

Laser welding depends on the right material and the right component sizes. We primarily process high-quality stainless steel alloys, which are characterized by high load-bearing capacity, corrosion resistance and durability. Whether thin-walled precision components or larger workpieces, we weld material thicknesses of up to several millimetres without compromising dimensional

accuracy and quality.

Thanks to the precise control of the laser beam, extremely fine, resilient weld seams are created with minimal heat input – no distortion, no material changes, maximum stability. Even complex contours and filigree structures can be realized with tight tolerances, so that every component is manufactured exactly according to your specifications.

- The finest precision components through to larger workpieces

- Welded joints for filigree structures & complex geometries

- Medical instruments, industrial components & custom-made products

- High dimensional accuracy with different material thicknesses

FAQ

Frequently asked questions

What are the costs for laser welding?

The costs depend on various factors, including material, component size, weld seam length and quantities. Simple welded joints are cheaper, while complex geometries or special materials are more expensive. We would be happy to provide you with an individual quote at – tailored to your requirements.

What can be welded with laser welding?

Laser welding is ideal for high-precision applications in medical technology, particularly in the manufacture of surgical instruments. Thanks to minimal thermal stress on the material, this process enables the production of delicate and complex components with maximum precision and stability. In addition, laser welding guarantees smooth, pore-free weld seams that meet the strict hygiene requirements in medical technology.

What quality controls are carried out during laser welding?

Every weld seam undergoes strict quality checks for dimensional accuracy, stability and surface quality. Depending on the requirements, we use visual inspections, microscopic analyses or non-destructive testing methods. In this way, we ensure that only absolutely precise and flawless workpieces leave our production facility.

What minimum quantities or batch sizes are possible?

We manufacture individual items, small series and large series – customized to your requirements. The minimum quantity depends on the complexity of the component. Thanks to flexible production capacities, we offer customized solutions, even for specific quantities. Just get in touch with us.